Even in the modern context of strong automation in the manufacturing process, the human sensitivity and perception cannot be substituted by a robot line in some specific tasks.

For these operations, the manual intervention of the worker is also compulsory to avoid damages from mechanical parts or tools.

Gloves for special use: the study

These gloves protect from risks (such as the onset of work-related diseases) which are not foreseen by the current standards.

For this reason, in order to test the performance of these gloves, we have collaborated with CTC Lyon: our historical partner for our in-house laboratory and the Certifications for our protective gloves.

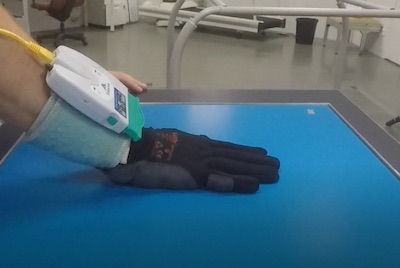

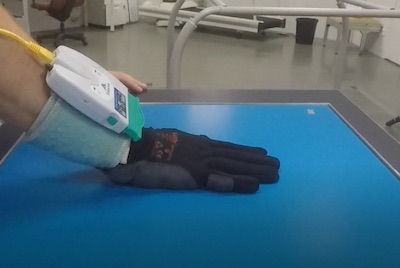

We have developed with the CTC bio-mechanics laboratory 3 testing protocols exclusive to Safety Systems HP based on sensors measuring the dampening of energy transferred to the hand. The test were realized firstly at bare-hand (zero dampening) and secondly wearing the gloves to evaluate the dampening: the lesser the energy transferred to the hand (higher dampening), the higher the glove performance.

3 different studies have been carried out:

Special use gloves: impact analysis

INTENTIONAL IMPACT (metacarpal area, item GPRG72) the test was carried out by an operator by hitting repeatedly a platform with the metacarpus. This platform is equipped with a force detector in order to help the operator in making the test as homogenous as possible, by avoiding variable impacts.

Special use gloves: applied pressure analysis

APPLIED PRESSURE (palm area, items GPRG74, GDY437V, GDY438VI) The test was carried out throughout a 6-axe robot and 3D printed hand to simulate the human hand. In this case, the robot repeatedly applied pressure on the platform at a constant force.

APPLIED PRESSURE (fingertips area, items GPRG73, GPRG74) the test was carried out by an operator by repeatedly applying pressure on the platform with the fingertips.