The immersion process, also known as dipping, is one of the most widely used and versatile methods for manufacturing coated work gloves

With this method, it is possible to produce gloves with highly diversified properties — from mechanical strength to waterproofing, from grip to chemical protection — to meet the needs of many industrial sectors. It is precisely this flexibility that makes dipping a key solution in the personal protective equipment sector.

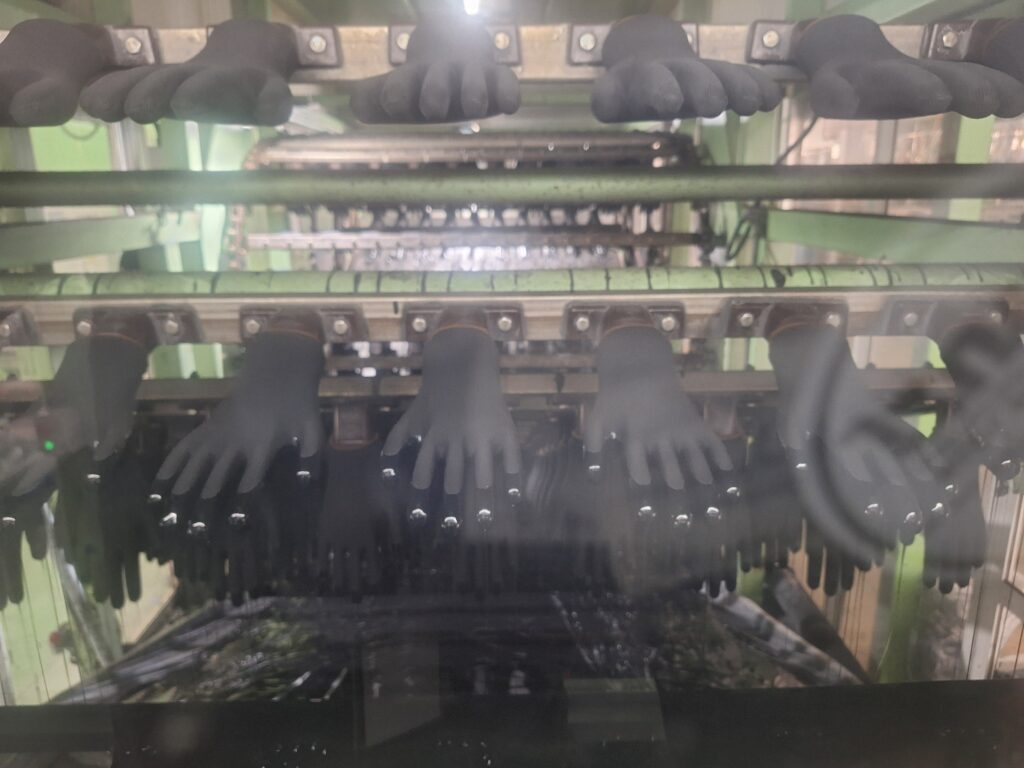

Dipping is an industrial process whereby a mould (hand-shaped in the case of gloves) is immersed in a liquid solution containing polymeric materials, such as natural latex, nitrile, neoprene or polyurethane. Once removed from the bath, the mould retains a uniform coating of material which, through subsequent drying and polymerisation steps, transforms into the actual glove.

Depending on the properties required for the glove, the dipping process can be performed according to different modalities:

Choice of material is equally decisive. Natural latex ensures elasticity and comfort, but can cause allergies. Nitrile is an excellent hypoallergenic alternative, highly resistant to oils and chemicals. Neoprene is valued for its good chemical and thermal resistance. Polyurethane (PU) stands out for its lightness, breathability and dexterity.

Each material gives the glove different properties, making it suitable for specific work environments.

The dipping process consists of a series of steps, all of them essential to ensure the quality and the desired properties of the final product. It starts with the preparation of the moulds, which are generally made of ceramic, aluminium or glass. The moulds are thoroughly cleaned to remove any impurities and residues and, in many cases, are heated to promote better adhesion of the material.

Some production processes include a coagulation phase, during which the moulds are submerged in a coagulating agent, such as calcium nitrate. This accelerates the solidification of the polymer upon coming into contact with the surface of the mould. This step is followed by immersion in the polymer, which is the central phase of the process: its duration and the viscosity of the solution determine the thickness and the characteristics of the glove.

Once removed, the moulds undergo a dripping and pre-drying phase, during which excess material is eliminated and the structure of the glove begins to stabilise.

After that, the gloves undergo vulcanisation or polymerisation in special ovens, an essential step to give the material elasticity, strength and stability. After cooling, removal and finishing take place: the gloves are removed from the moulds and, in the case of disposable gloves, may undergo additional treatments such as chlorination, or powdering to make it easier to put them on. Finally, the gloves are checked and packaged.

The dipping process offers many advantages from a production and functional viewpoint. It ensures a high degree of flexibility, making it possible to adjust thickness, texture and type of coating to meet specific requirements.

It is a process that can be readily automated for large-scale production and offers extensive possibilities for customisation, including multi-layer coatings and areas with different performance characteristics.

Precise control of each step ensures high and consistent quality standards over time.

Thanks to these characteristics, gloves produced via dipping find use in many sectors:

To complete the overview of the dipping process, in recent years the sector has experienced a period of significant evolution, driven by technological innovation and a growing focus on environmental sustainability. The introduction of biodegradable materials has reduced the environmental impact of gloves, while touch-screen technologies make it possible to use electronic devices without compromising on protection. These solutions are complemented by antibacterial coatings, which are more and more in demand to ensure high standards of hygiene in sensitive environments.

At the same time, many companies are investing in low-energy production processes and water and material recycling systems, so that, besides becoming increasingly efficient and versatile, the dipping process is more and more responsible from an environmental standpoint. This evolution confirms the pivotal role of this process in the production of work gloves, both today and in the future.

For more information write to marketing@lanzigroup.com.