Single-use gloves have been widely discussed over the last few years, and we have certainly had reasons to wear them. However, the many varieties of single-use gloves available on the market can be confusing, especially considering the many models created for different professional and industrial sectors.

Single-use gloves, more commonly referred to as disposable gloves, are part of the Chemical Protective Gloves category and can be divided into the following types according to the material that they’re made from:

Single-use gloves, as we know them today, were first invented in 1964 by a historic company which was inspired by the techniques that were used to manufacture condoms.

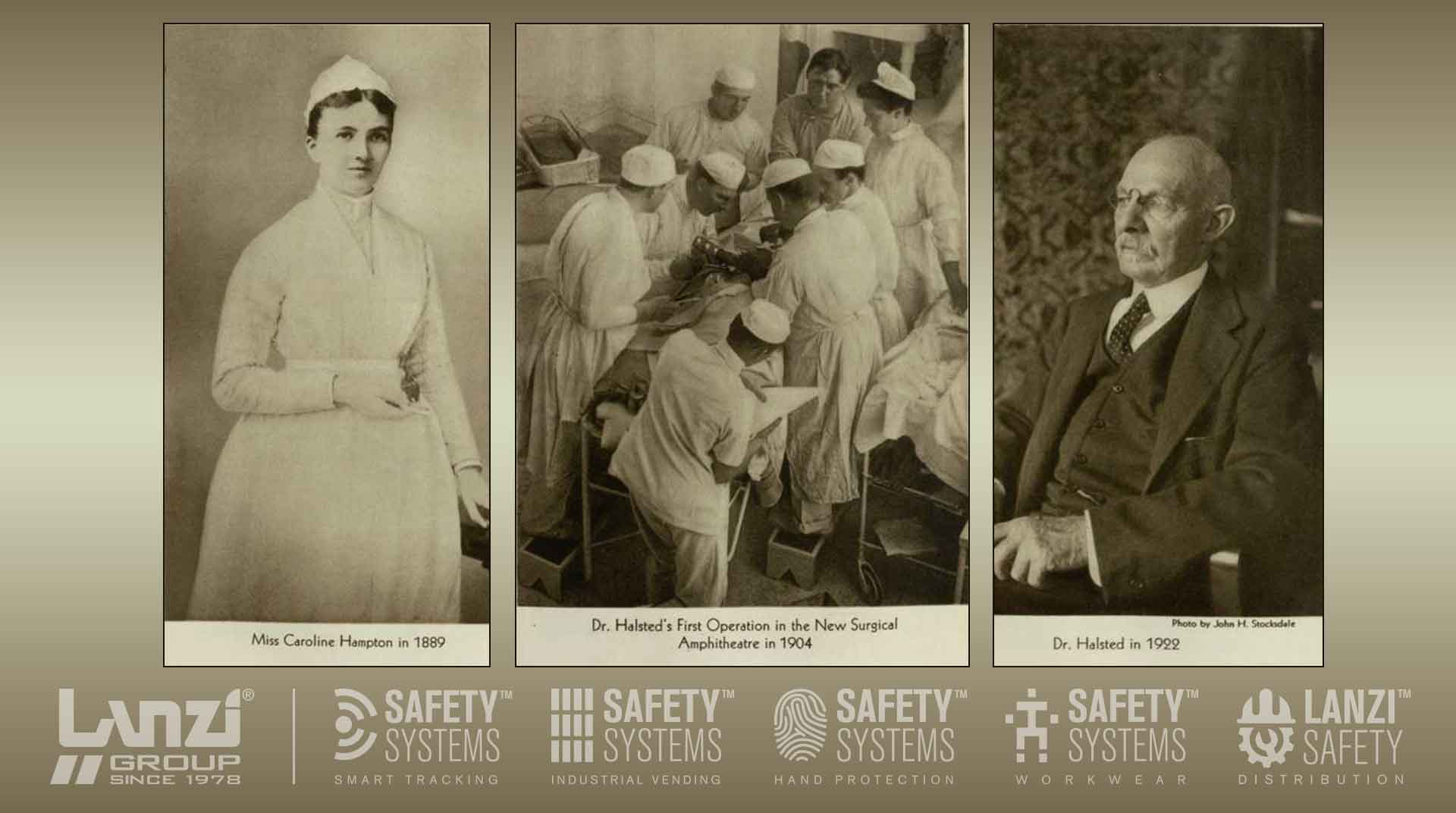

We have to go back almost one hundred years to trace the origins of the first surgical gloves in history, which were created to protect the hands of Caroline Hampton, head nurse at the operating theatre of Johns Hopkins Hospital in Baltimore, in 1889.

At the turn of the century, due to severe dermatitis caused by the use of phenol derivatives for hand disinfection in the operating theatre, the nurse informed the chief surgeon of her intention to leave the job – a role where she had shown so much passion and skill.

The doctor felt Miss Hampton was indispensable, and issued a request to Goodyear Rubber Company to produce a customised pair of gloves for his head nurse. This allowed Ms Hampton to keep working in the operating theatre, and a few months later the assistant doctors began wearing the rubber gloves too.

The differences between the types of single-use gloves can be found in the materials used, which determine the specific use of each disposable glove currently on the market.

Talc or powder act as lubricants to make the glove a good fit. The powder is made of corn starch, which is bio-absorbable by the dermis and GM-free. Since the gloves contain no gluten, they can also be used in food processing for coeliacs.

To reduce the risk of allergic reactions, single-use gloves without powder are also now being used. There are many processing techniques, such as chlorination and polymerisation, which make it easier to slip single-use gloves on and off even without the powder.

These are made with synthetic raw materials such as PVC (polyvinyl chloride). Adding plasticisers provides malleability, mouldability, softness and elasticity. They are widely used in hospitals for economic reasons, even though they have less sensitivity and resistance than nitrile gloves.

These are the best choice for elasticity, mechanical and chemical strength, sensitivity and ergonomics. Although the gloves are still single-use, the nitrile material (acrylonitrile and butadiene) makes them ideal for situations such as handling food (except those containing alcohol), or when working in contact with chemical substances and/or bodily fluids, which requires the highest levels of protection.

Single-use gloves made with natural latex (from the rubber tree) have a greater resistance to puncturing and tearing. They are biodegradable and ensure a high level of sensitivity, elasticity and impermeability.

Rubber latex gloves are often used by doctors and dentists for their elasticity (including at low temperatures), since it is the most elastic material in existence (latex-insulated rubber instantly takes the shape of the inserted hand and then, even after being stretched and squeezed, returns to its original shape).

Polyethylene gloves comply with all European Community food safety regulations, and are mainly used to protect hands and handled objects from dirt. They are so practical that they are also perfect for use in the home, and not just professionally.They protect the skin, ensure hygiene and provide excellent sensitivity to touch.

These are recommended for all uses. Their resistance, elasticity and comfort properties make them ideal for use in many fields of application, providing first-rate protection against chemical substances (detergents, acids, and alcoholic, greasy or oily substances). They offer great sensitivity and reduced hand fatigue, remaining comfortable even after prolonged use.

For more information, write to info@lanzigroup.com